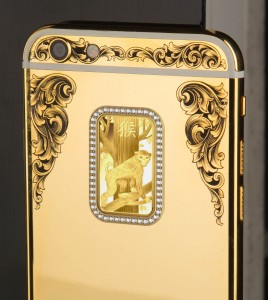

In the past few months I’ve been making and engraving a few very exclusive and high end custom iPhone backplates and casings. Their final destination was in Qatar.

Starting off with a simpler ones, here are two engraved models, where the engraving was done directly on the case

Engraved iPhone 6

Engraved iPhone 6

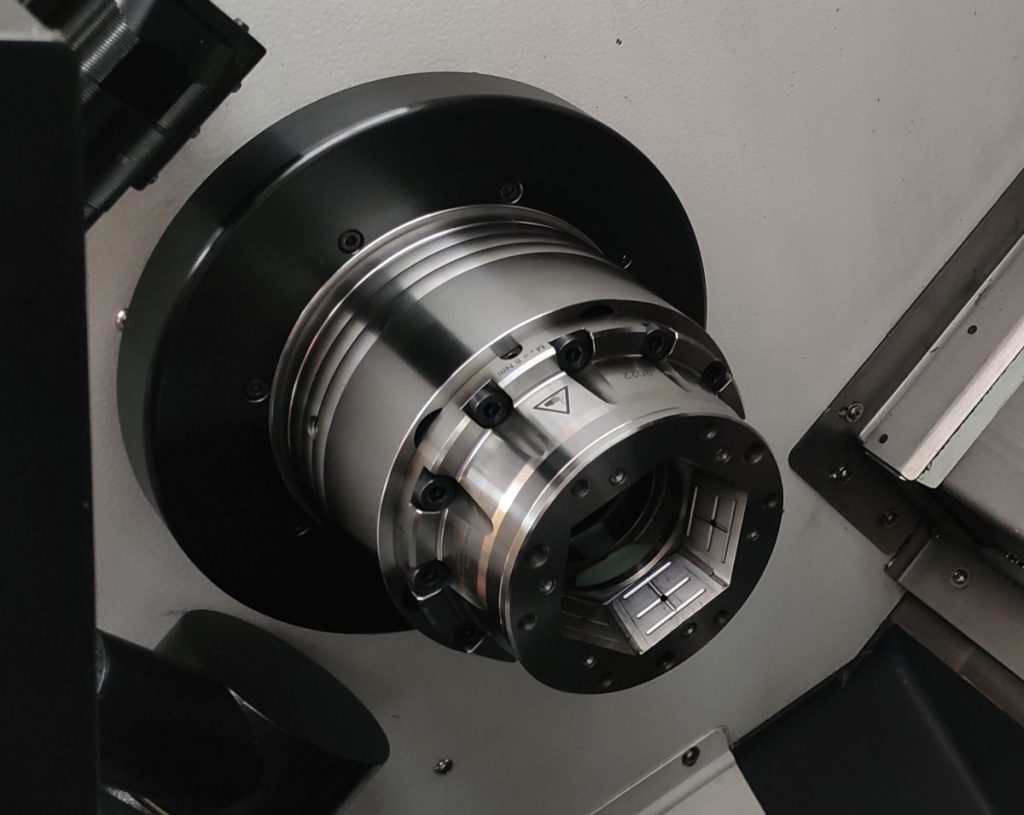

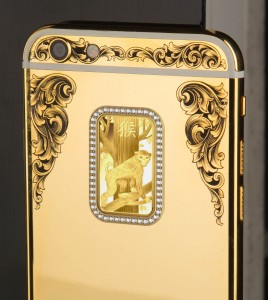

A bit more interesting model is the iPhone 6 with custom backplate. The backplate frame was CNC milled from silver sheet, engraved and plated with 24K gold. The corner triangles are also from silver sheet. Inside rhombus features black and white Mother of Pearl mosaic. This was a very interesting project, because I got to do all the 3D modelling work for CNC, milling and engraving. Basically from start to finish, except the gold plating. It’s so cool to see the final result at the end after many-many days of work.

Engraved iPhone 6 with silver corners and Mother of Pearl mosaic

Engraved iPhone 6 with silver corners and Mother of Pearl mosaic

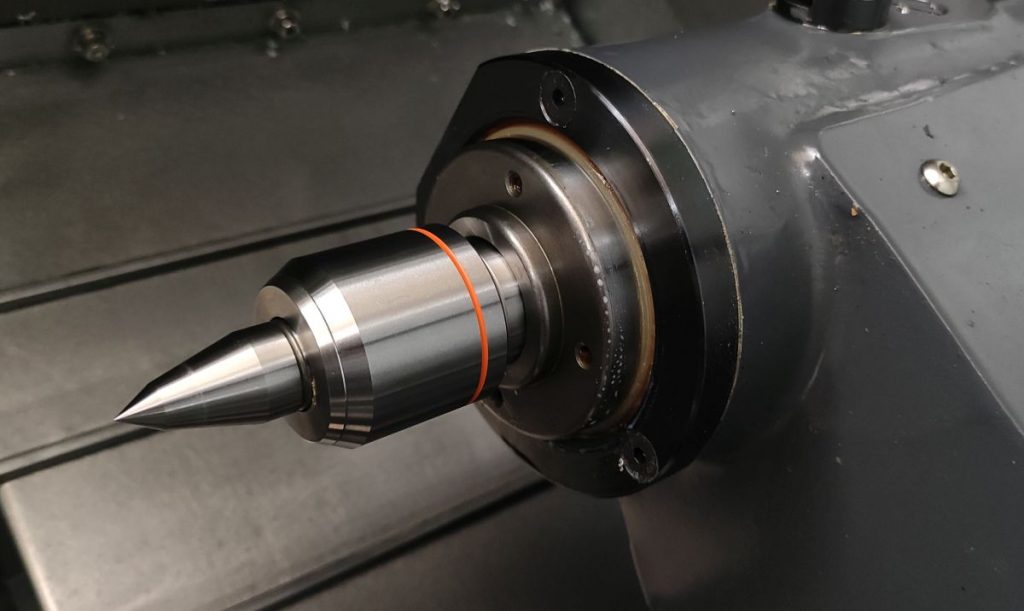

The prettiest one, I think, is this one with bulino engraved Arabian horse and gyrfalcon corners. Bottom corners feature Qatar skyline. As this was made exclusively for Qatar, then then center round piece has their logo and outside rectangle has Islamic pattern.

iPhone 6 with silver corners and Mother of Pearl mosaic

As always, do follow me on Facebook, Instagram and Twitter. I post more frequent updates there.